Health Status and Durability Analysis

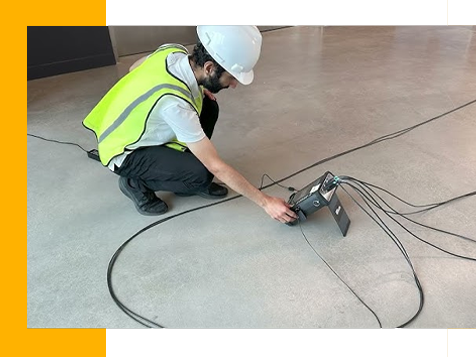

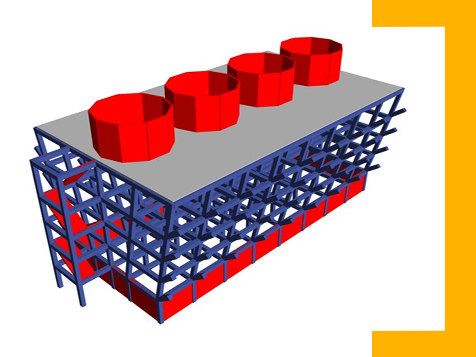

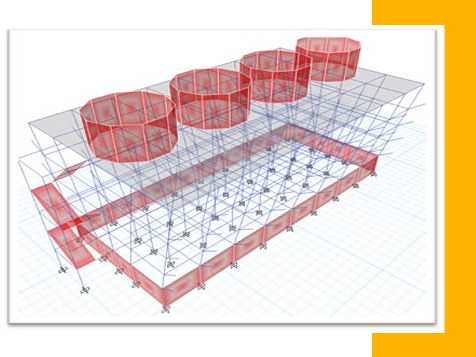

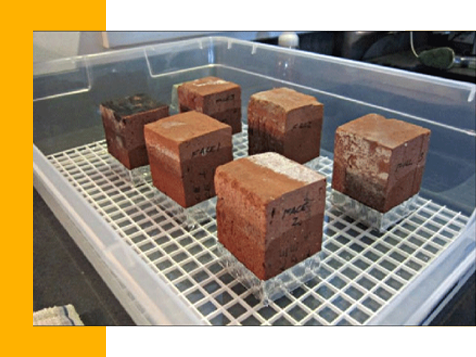

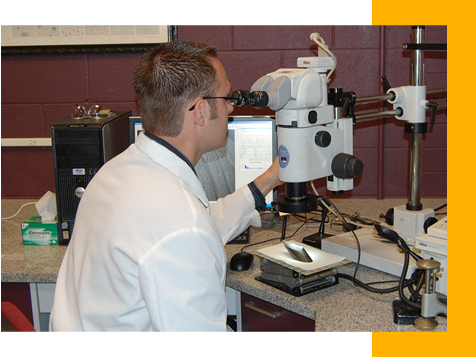

Conducting cover meter test at selected locations on RCC members of the structures covered under the study to see the adequacy of concrete cover to rebars and creation of Contour Mapping of cover depth in RCC Structure by using (working on Magnetic field generation concept) steel bar scanner as per IS:456:2000 and relevant code of particular structure